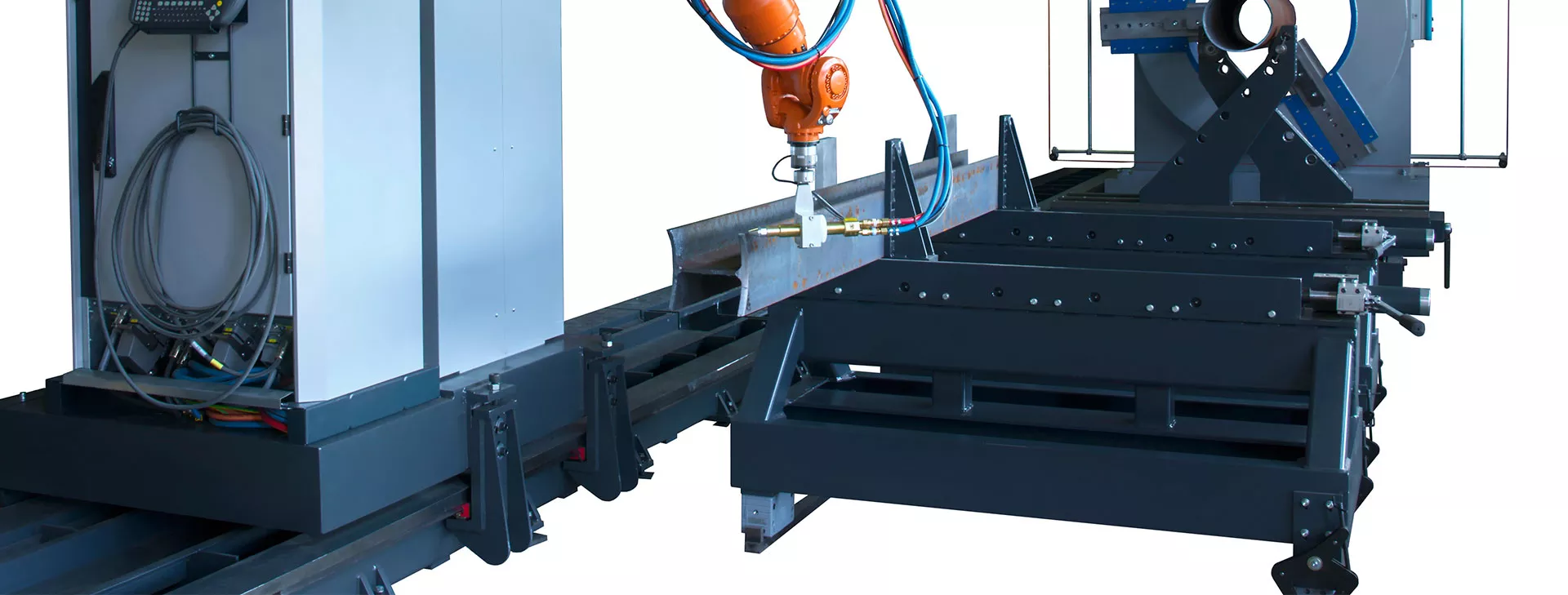

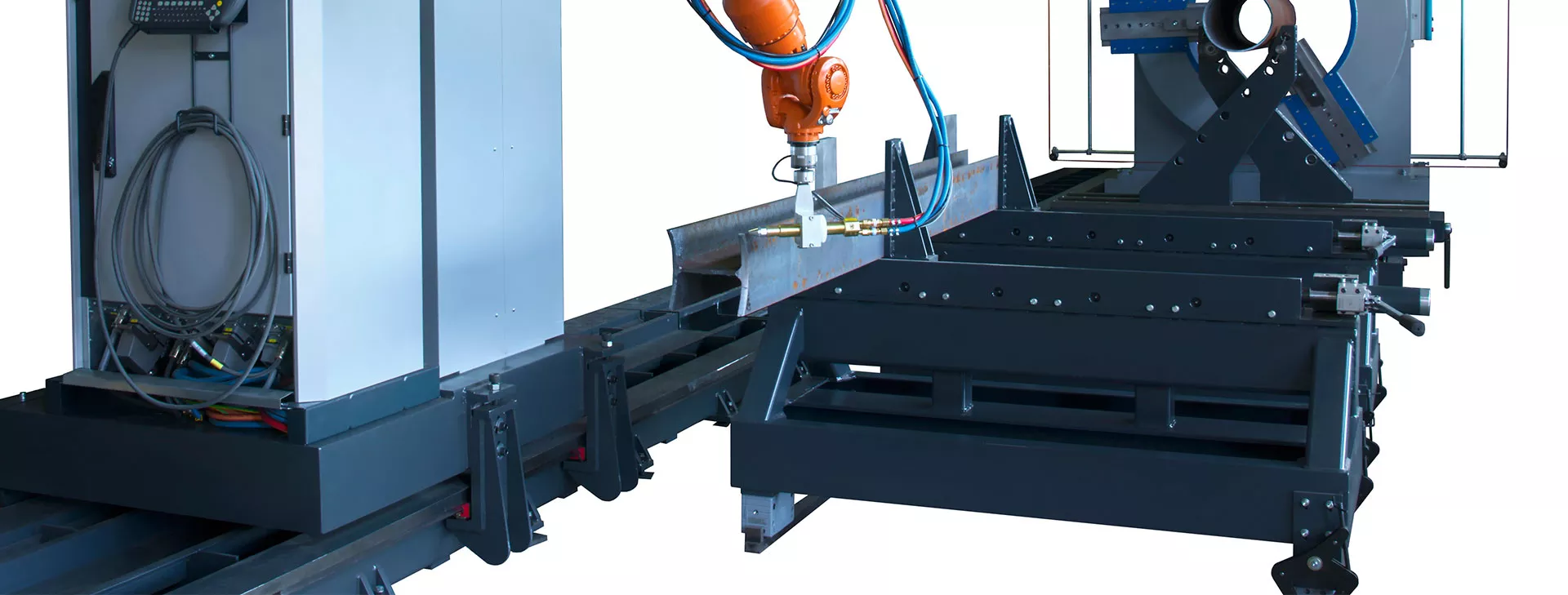

The PB Robo series covers robot-controlled machines that are mainly intended for the comprehensive cutting of beams (H, U, L and I). They are also capable of cutting round pipes and square & rectangular pipes. Beams can be cut up to a web width of 1,200 mm and up to a weight of 12 tonnes. The maximum dimensions for round pipes and square & rectangular pipes can be seen in the table of technical data.

If the various workpieces – beams, square & rectangular pipes or round pipes – are to be profiled, the machines are equipped with 9 CNC-controlled axes.

Detailed information can be supplied on request.

with 8 CNC axes for beams with a maximum width of 1,200 mm and round pipes with a maximum width of 1,220 mm inclusive of oxy-fuel cutting system, fixed chuck, beam cutting bed and height-adjustable, scissor-type pipe carriage

with 9 CNC axes for beams with a maximum width of 600 mm, for square & rectangular pipes with a maximum size of 420 x 420 mm and for round pipes with a maximum diameter of 1,000 mm inclusive of oxy-fuel cutting system, height-adjustable chuck and motorized conveyors for infeed, cutting and outfeed

| Technical information / Machine series: | PB 200 Robo | PB 600 Robo | PB 800 Robo | PB 1200 Robo |

|---|---|---|---|---|

| Weight of standard machine in kg: |

7,000 | 12,000 | 13,000 | 16,000 |

| Number of CNC axes: | 7-9 | 7-9 | 7-9 | 7-9 |

| Max. workpiece weight in kg: | 4,000 | 8,000 | 12,000 | 12,000 |

| Min. - max. clampable round pipe diameter in mm: |

50 - 406 | 50 - 610 | 50 - 812 | 50 - 1,220 |

| Max. size of chuck opening in mm: |

400 | 400 | 400 | 650 |

| Min. - max. clampable square & rectangular pipes dimension in mm: |

100 x 100 / 260 x 260 |

100 x 100 / 260 x 260 |

100 x 100 / 260 x 260 |

100 x 100 / 420 x 420 |

| Min. - max. clampable beams width in mm: |

50 - 200 | 50 - 600 | 50 - 800 | 100 - 1200 |

| Min. - max. clampable diameter for dished ends in mm: |

- | - | - | - |

| Min. - max. cuttable workpiece length in mm: * |

300 - 12,000 | 300 - 12,000 | 300 - 12,000 | 300 - 12,000 |

| Min. - max. wall thickness in mm for cutting with oxy-fuel /plasma in mm: * |

5-120 / 1-80 |

5-120 / 1-80 |

5-120 / 1-80 |

5-120 / 1-80 |

| Max. torch angle in: ° | +/- 70 / 45 | +/- 70 / 45 | +/- 70 / 45 | +/- 70 / 45 |

* With torch in vertical position